Case Study: VR in Engineering

My Role: UX Research & Design Lead

- Led end-to-end user journey for a VR interface design, designed VR interfaces, optimized user flows

- Conducted user interviews and task analysis with civil engineering partners from research team to ensure the VR system accurately reflected real-world workflows and upheld the precision expected of an engineering inspection program

- Collaborated cross-functionally with civil engineering partners and research team

Our Goal?

Traditional engineering inspection processes typically consist of manual, on-site evaluations using visual assessments, measurements, and testing to identify structural issues and ensure compliance with safety standards. This is usually time-consuming and hazardous due to manual data collection, difficult access to structures, exposure to environmental risks, and the physical demands placed on inspectors in potentially dangerous settings.

In order to mitigate these risks and achieve a safe, efficient inspection process, we thought of an unconventional and daring way to do just that: a VR environment that simulates real-world structures in which engineers can conduct structural inspections remotely. This experience was created for civil engineers, who regularly inspect large structures such as bridges, tunnels, and buildings to ensure safety and structural integrity. The environment recreates these structures in a digital environment. Using a VR headset, professionals can walk through and practice inspections without being on-site. This helps reduce risk and makes inspections more accessible and efficient.

The Challenge

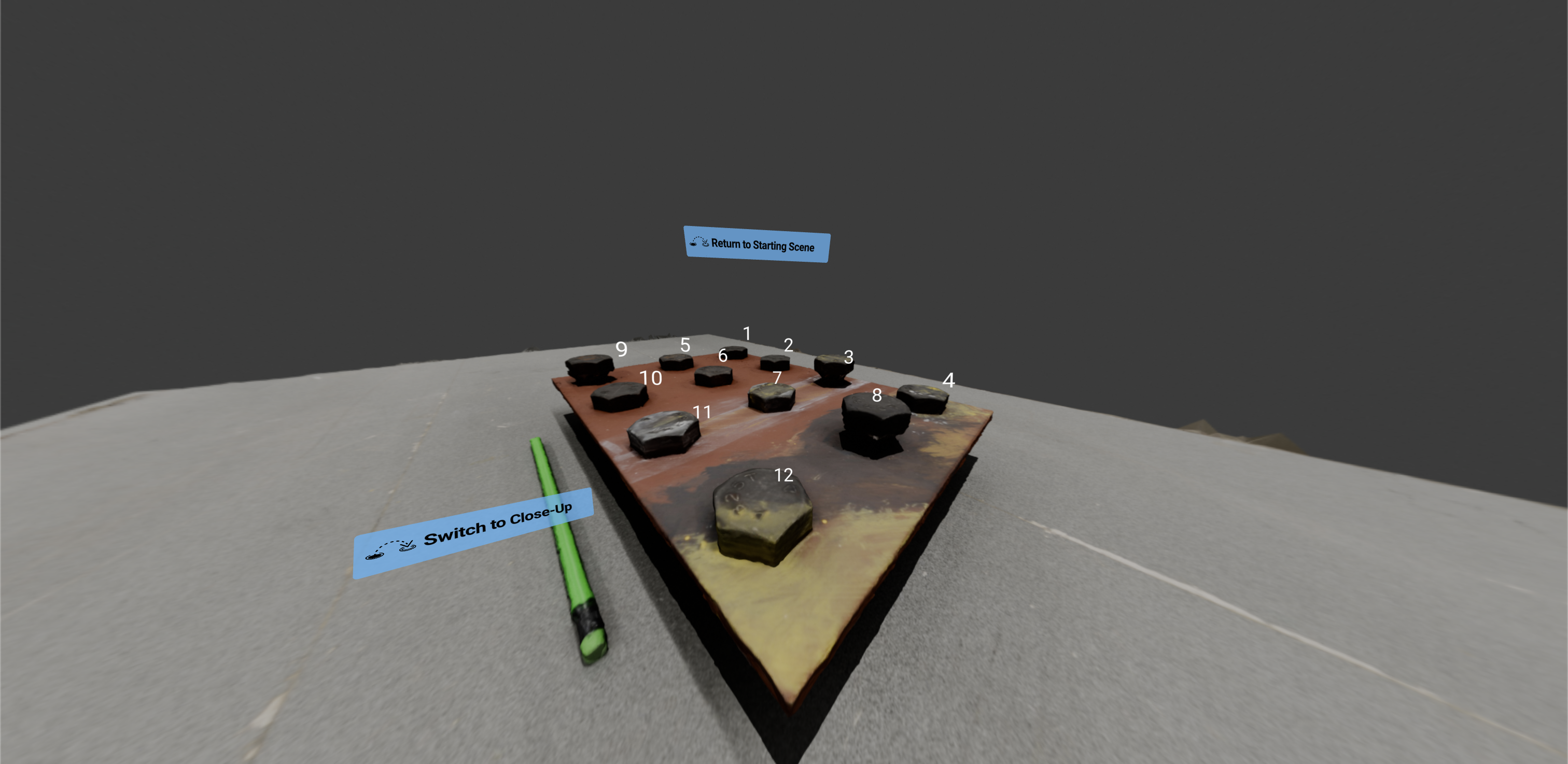

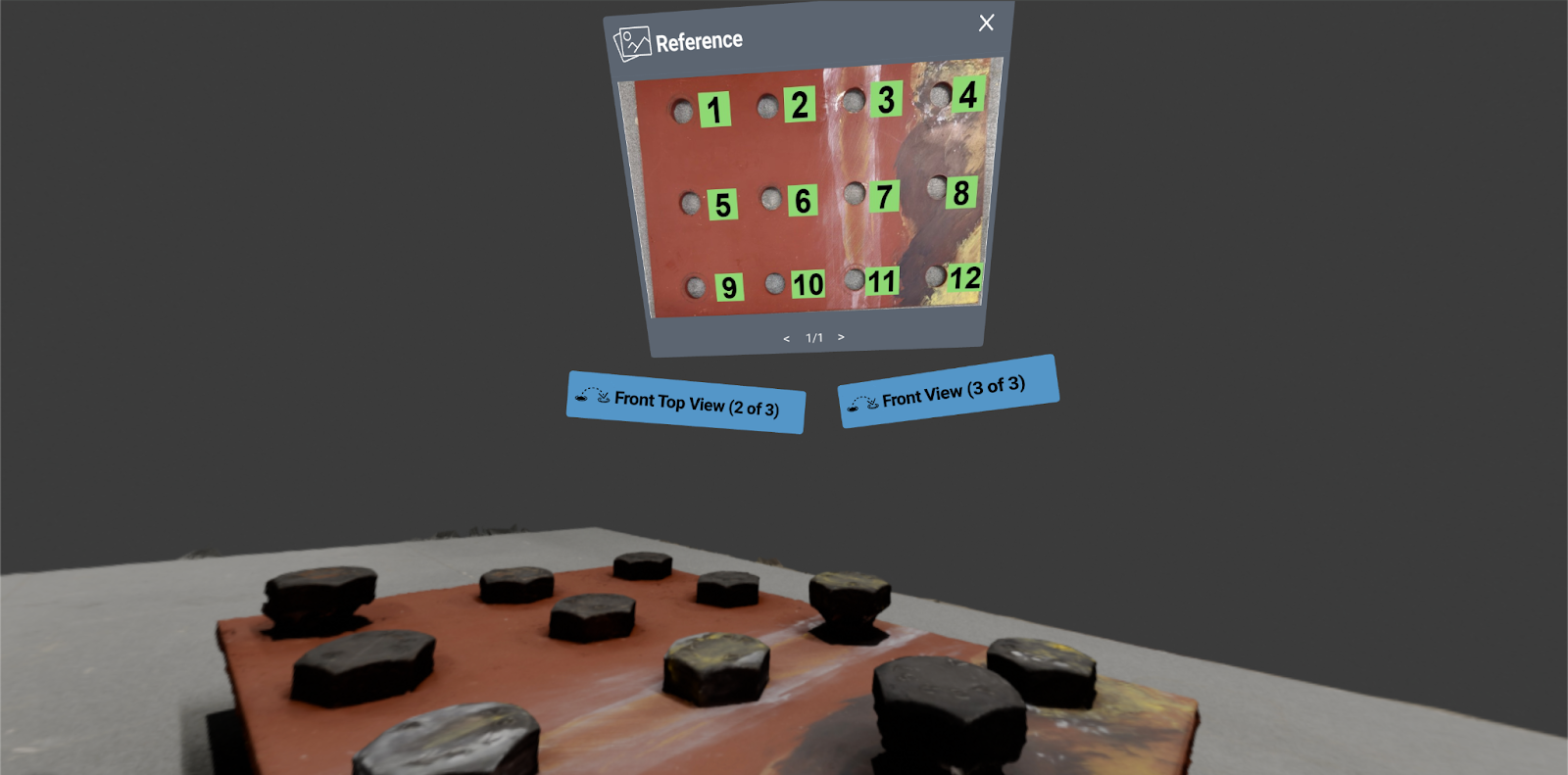

For our initial VR environment, we used a model of a steel plate, a piece that is common in construction projects such as buildings and bridges, with twelve holes with bolts inserted. The model was created in Blender, a 3D model creation software, and subsequently imported into the VR environment. The testing phase consisted of having engineers identify loosened bolts, as well as navigate through different views of the structure. However, initial prototypes overwhelmed users: cluttered labels, unclear navigation, and inefficient user flows impeded inspection efficiency.

Prototype 1: The initial prototype featured distracting labels and a congested navigation

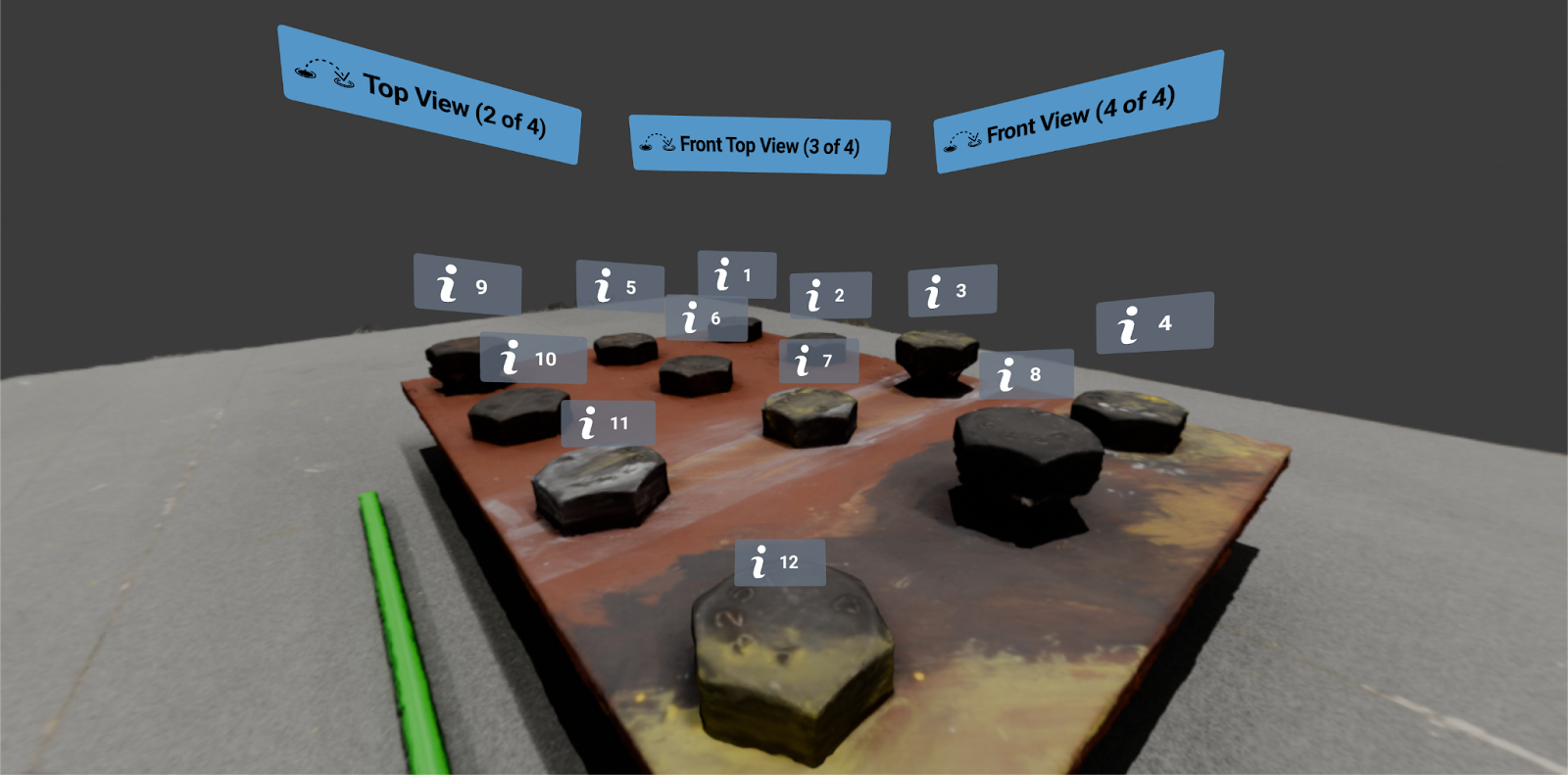

Prototype 2: The second prototype featured an image of a real-life steel plate for reference with numbered labels, which was found to be ineffective through testing due to incorrect matching of numbers from the reference image to the VR model in some tests

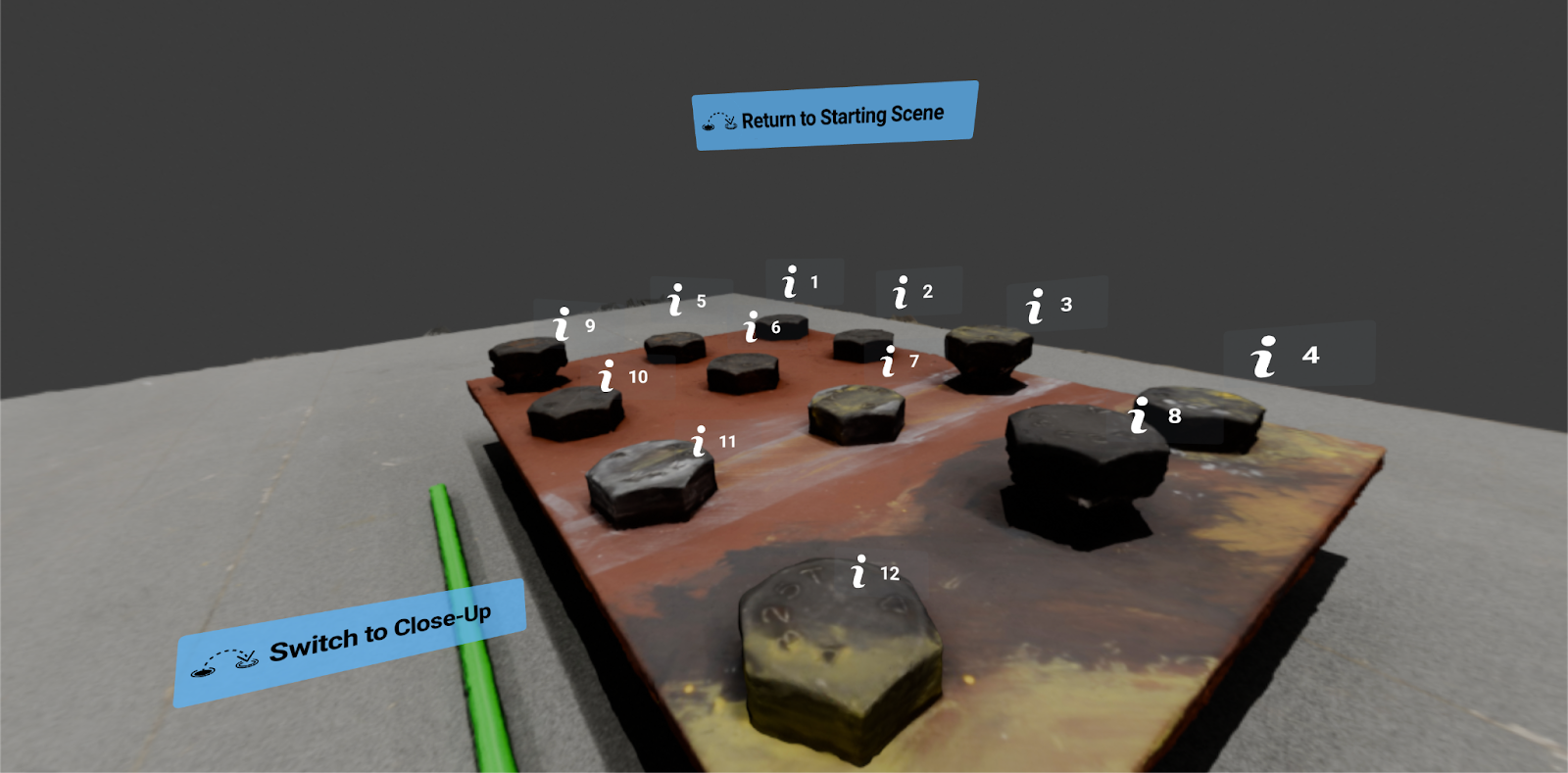

Prototype 3: This prototype proved to be much more effective through testing, with the only common feedback being that the information symbol being mildly distracting

Process

1. Background Research & Task Mapping

I shadowed two engineers over the course of a week and ran interviews with five engineering students to understand:

- How they prioritize inspection points

- What visual and data cues they rely on

- How they document strucutral issues

From this, I mapped a typical inspection task flow:

Enter environment → Locate stress points → Assess → Capture visual evidence → Log details

2. Heuristic Audit of the First Prototype

The original prototype had:

- At least 12 buttons visible at all times

- Ambiguous labels

- Visually distracting guidance system

Testing showed users were:

- Spending 3x more time completing inspection sequences

- Often missing critical defects due to interface clutter in the form of bolt labels

Design Iterations

1. Information Hierarchy Overhaul

Due to the interface clutter, which led to ineffectual inspections, I removed excess buttons and consolidated navigation options. The default UI would now show only essential tools: movement, labels.

The navigation options were spaced out to remove clutter and be less visually exhausting. The real-life reference image was removed as it was determined through testing that users understood what the model was.

2. Bolt Labelling

The main culprit of inspection inaccuracy was the size of the labels. To rectify this, I:

- Removed existing labels with background colors

- Added just a number to label each bol; no background, no description

Validation and Testing

- Conducted 5 rounds of usability testing with 45 test subjects consisting of civil engineers, with a balance of male and female subjects, as well as level of study

- Users were tasked with identifying loosened bolts and navigate through every view

- Used task completion rates, Post-Activity Survey and System Usability Scale (SUS), to understand qualms users may have had, confirm strengths, and make appropriate changes based on feedback

Results:

| Metric |

Before Redesign |

After Redesign |

| Avg. Task Completion Time |

4 min |

2 min |

| Task Accuracy |

80% |

100% |

| SUS Score |

59 |

94 |

| Reported Cognitive Load |

High |

Low–Moderate |

Usability testing showed major improvements after the redesign. Task completion time was cut in half (from 4 minutes to 2), and accuracy rose from 80% to 100%, meaning users could complete inspections faster and without mistakes. The System Usability Scale (SUS) score jumped from 59 to 94, reflecting a much better user experience, while reported cognitive load dropped from high to low–moderate. These results confirmed that changes like simplifying the layout, showing only relevant tools at the right time, and improving clarity helped users stay focused and confident. The insights directly shaped the final design, making the VR interface more intuitive, efficient, and aligned with how inspectors actually work in the field.

Impact

- Received positive feedback from civil engineering students; no complaints were logged after launch

- Piloted and advanced by Fresno State’s civil engineering department

- Research paper co-authored with faculty accepted into and presented at the 46th Annual Central California Research Symposium

- Research paper submitted to 2026 SPIE AR/MR/VR Conference

Key Takeaways

- Designing for VR means thinking beyond a flat screen; information and actions are placed in a 3D space around the user, making it imperative that everything is easy to see, reach, and understand without feeling overwhelming

- Simplifying doesn’t mean removing features — it means showing the right tools at the right moment, based on what the user is doing. This helps reduce clutter, keeps the interface focused, and makes it easier for users to stay on task without getting distracted or overwhelmed

What I'd Do Next

- Add haptic feedback for more immersive detection of defects

- Personalize UI based on inspection experience level

- Integrate AI assistance to flag potential issues in real time

Tools Used: